Dust Collectors: Dust-Master

Cincinnati Fan manufactures seven sizes of the Dust-Master Portable Dust Collector. The two-stage filtration design provides much higher filtration efficiencies than single-stage collectors.

PERFORMANCE RANGE:

Capacities for Portable Models:

- Capacities up to 1300 CFM

- Static pressures up to 10″ SPWG

- Air stream temperature to 104° F (40° C)

- FEATURES & BENEFITS

- OPTIONS

- APPLICATIONS

- RESOURCES

Features

- AMCA Type B construction on all models with explosion proof motors.

- Spark resistant, self-cleaning, cast aluminum, and radial wheels are standard.

Totally enclosed motors are standard. - Motors are continuous duty, full horsepower rated. NOT duty rated.

- Heavy-duty 14 gauge steel blower housing is standard on all models.

- 1/3 – 3/4 horsepower models standard with a 10 micron dust bag. 1-3 horsepower models standard with a 5 micron dust bag. 1 micron bags are available on 1 to 3 horsepower models. All dust bags are 99% efficient at their specified micron filtration levels.

- All models available with 3 Phase, 230/460 Volt, 60 Cycle motors. 1/3 HP up to 2 HP models are also available with 1 Phase, 115/230 Volt, and 60 Cycle motors.

- EXP, 575 Volt, and 50 Cycle motors are also available on most models.

- Single phase, totally enclosed motors (up to 1 HP) come with an 8 foot cord, 3 prong grounded plug, and a switch pre-wired for 115 Volt, 60 Cycle.

- Drum lids on 1/3 to 3/4 HP models fit over standard 30 gallon steel garbage cans or 35 gallon steel or fire-resistant, fiber drums having a maximum diameter of 20-1/2”.

- Drum lids on 1 to 3 HP models fit over standard 55 gallon steel drums or foil lined, fiber drums having a maximum diameter of 24”. Fiber drums must be able to support the unit weight.

- Drums are not included and plastic drums should never be used for any models.

Benefits

High Efficient Two-Stage Design:

Our two-stage design is far more efficient than a 1 stage design. The heavy dust and chips, or abrasive material are separated in the cyclonic separator in the first stage and only the lighter dust passes through the blower to the second stage filter bag. Single-stage collectors draw all the large, heavy, abrasive dust into the blower which causes rapid wearing of the blower wheel and housing and can very quickly cause a dangerous wheel unbalance problem. It offers superior efficiency.

Spark Resistant Wheels:

Spark resistant, self-cleaning, cast aluminum radial wheels are ideal for dust collection applications. They are spark resistant to reduce the chance of fires and the radial design minimizes dust build-up on the wheel that would cause excessive vibration leading to premature wheel and/or motor bearing failure. They are much safer than steel wheels.

Safer Working Environment:

By collecting dust and grit “at the source,” you won’t need to vacuum the floor. It is also much easier to see the part you are working on without the dust and debris clouding your view. By utilizing 10, 5, or 1 micron filter bags, the operator can breathe in much cleaner air. It provides a much healthier working environment.

Rugged Construction:

Heavy-duty construction of all fan components provides long, dependable service. There are many Cincinnati Fan Dust-Master Dust Collectors still in operation in home workshops and factories for over 20 years, offering many years of dependable service.

Made in the USA:

In an era when small machinery manufacturing is continually going overseas, we are proud that Cincinnati Fan Dust-Master Dust Collectors are still made and assembled in our factory in Mason, Ohio.

You will find imported products, some of which are near copies of our design and/or claim to be as efficient or deliver more CFM. If you do, first ask them for certified performance data. Ours is in our catalog. Your selection should not turn out to be a disappointment. Compare the features, benefits, and component material.

We also offer many accessory nozzles, reducers, hoses, clamps, dollies, and dust bag materials to fit our units. Imported models don’t offer these additional system components. And, who will you call for assistance or service? Help support the USA.

Engineering Assistance:

Our catalog contains information on how to select the proper size dust collector and filter bag material. No guesswork necessary.

Model HB Dust Bag

Model DB Dust Bag

Dolly Base

“Y” Connector

Inlet Suction Nozzle

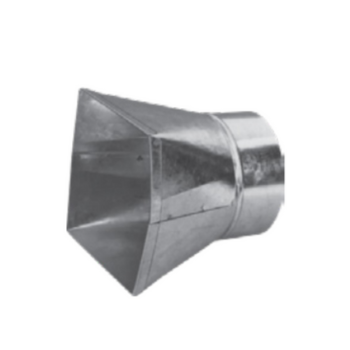

Tapered Reducer

Flexible PVC Hose

Hose Kit

Hose Clamp

Hardware Kit

- Dust collection for woodworking

- Dust collection for grinding and buffing machine

- For portable or stationary applications

FIND YOUR LOCAL SALES REP

Exceptional local support with over 170 experienced sales engineers in 56 offices strategically located across the U.S. and Canada to assist you.

START HERE